While sugar is the source of most biofuels, getting it is rated as the key set of reactions that can bring down the cost of advanced biofuels, closer to that of the dangerous (to the environment) petrofuels. In the US, one of the key labs in renewable energy research generally is the Lawrence Berkeley Lab. On cue, they have just released data which leads us to the conclusion that they've cracked this problem, using agricultural waste they refer to as cellulosic biomass.

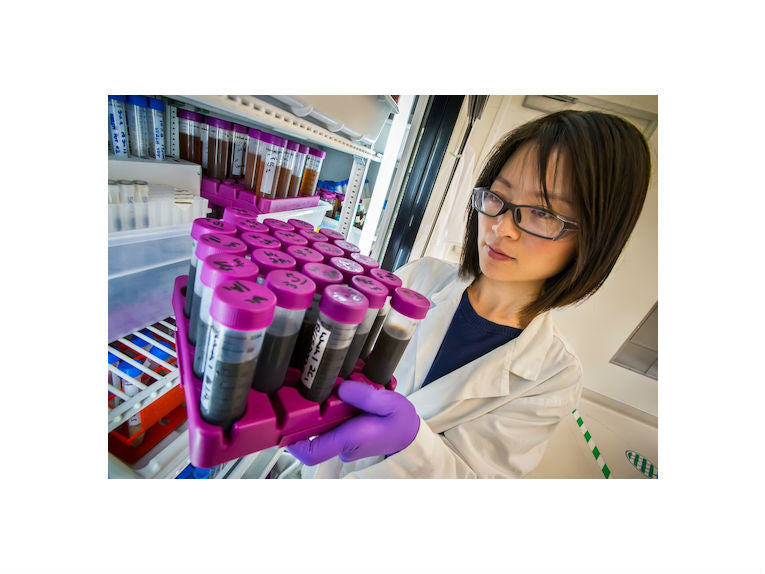

Blake Simmons is the Head of the Deconstruction Division of the Joint BioEnergy Institute and explains that they use acid as a catalyst instead of enzymes. Sugars are released from lignocellulosic sources. The lignin rich ionic liquid is used only for recycling while the sugar rich water phase can be used directly. This also demands much less water during the process. Ning Sun is the lead author on several papers, shown here demonstrating for us the ionic liquids themselves. Her current paper in, "Biotechnology for Biofuels," is titled, "Production and extraction of sugars from switchgrass hydrolyzed in ionic liquids."

While 9 million metric tons of CO2 are added to our atmosphere every year, nobody can relax in the quest for carbon neutral energy sources. Fermenting sugars stretch back to the days when VW cars in Brazil were run on alcohol from sugar cane. Advanced biofuels are designed to cut out the carbon emissions. Using imidazolium chloride and an acid catalyst, Blake and his team have simplified the extraction of fermentable sugars. By adding sodium hydroxide, the ionic liquid could be recovered with the lignin, leaving 54% glucose and 88% xylose sugars. All that's needed now id the scaling up process for industrial level production and some tweaking of optimal conditions.