Many companies face a common problem: What to do with by-product or waste left over from the manufacturing process. Smart firms are increasingly finding profitable ways of turning waste into assets, often with the help of government agencies, such as the U.S. Environmental Protection Agency, a promoter of by-product reuse in regions across the U.S.

A Texas wire company offers a prime example. Wire cleaning operations are messy, leaving behind for this company, which made premium wire for fencing, an unwanted by-product: sulphuric acid with bits of rust in it.

It stopped viewing the sulfuric acid as a "waste" and started seeing the iron in the acid as an "asset" it could sell to a ferrous sulfate manufacturer. Changing the waste into a raw material wasn't easy, but the wire manufacturer turned $2.5 million in disposal costs into $315,000 in earnings.

With the Earth's regenerative ability no longer able to keep pace with human demand, people are turning resources into waste faster than nature can turn waste back into resources. To restore equilibrium, businesses, government, nonprofits, trade associations and academia are operating more sustainably by recognizing the economic value of their waste streams.

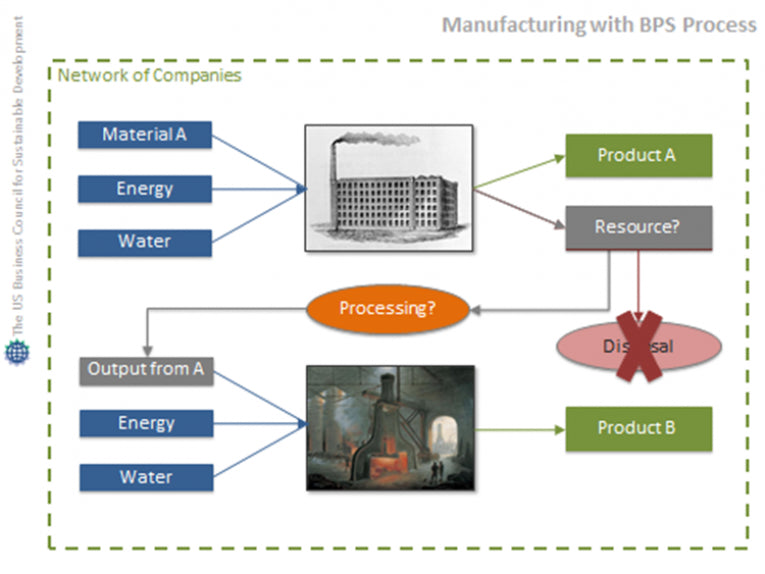

Compare the top graphic (Manufacturing with BPS Process), with this one for 'Typical Manufactoring Process

The premise of by-product reuse or materials exchange is simple: Under-valued wastes from one company are matched and used as a feedstock stream for another company. By-product reuse creates economic and environmental opportunities by creating new revenue or savings and by reducing the use of virgin materials, energy, water and creating a reduction in greenhouse gas (GHG) emissions.

These exchanges are often facilitated by local, state or regional networks coordinated by organizations that include the U.S. Business Council for Economic Development, Zero Waste Network in Austin, Texas, the Network for Business Innovation and Sustainability (NBIS) in Seattle, Wash., and ResourceFULL Use in Portland, Ore.

Businesses have many resources to draw from, including regional EPA offices. Here is how two regions are promoting by-product reuse.

By-product reuse in the Northwest

The Pacific Northwest Pollution Prevention Resource Center (PPRC) encourages businesses, local governments and NGOs to look beyond their traditional boundaries to pursue active exchanges for wastes.

Relying on strong community and regional partnerships, PPRC collaborated with the Zero Waste Alliance, the Columbia Corridor Association, the Department of Environmental Quality and the Portland Bureau of Planning and Sustainability to conduct an industrial needs assessment. The results clearly demonstrated that the Oregon market was ready for by-product reuse.

With grant funds from Boeing Corp., the partners and PPRC launched ResourceFULL Use, which brings together diverse businesses and organizations to identify potential by product exchanges. This network utilizes innovative matchmaking techniques, such as "speed dating," allowing participants to quickly meet and discuss opportunities. More importantly, the network takes a holistic approach to resource flows and offers participants technical assistance in mapping resources for their entire organization and not just a single material.

However, interactive workshops, coaching and training were not enough to maintain momentum. The network needed a technology platform that provided personalized and instant access to exchange information. A smart phone application is now in development and will have the following benefits:

By-Product Synergy Northwest is a network in Seattle, Wash., and a program of NBIS. NBIS facilitates the network through member meetings, sector working groups and other regional activities. The goals of the program include:

Giving new life to waste in the Midwest

The Mid-Ohio Regional Planning Commission (MORPC) received a grant from EPA's Office of Air and Radiation to integrate the Energy, Economy and the Environment (E3) initiative with the Ohio By-Product Synergy (BPS) Network.

The organization, Sustainable Ohio, manages the Ohio By-Product Synergy Network, which is a project of the U.S. Business Council for Economic Development (USBCED). Not only do participants receive clean, green and lean assessments through E3, but discover outlets for use of their by-products.

Initially targeted for the City of Columbus, the project expects to expand statewide with a goal of attracting 25 businesses in three years. GHG reductions of 264,000 metric tons over three years and a reduction of 125,000 metric tons of materials from landfills annually are projected.

This unified E3/BPS network brings together diverse partnerships between many impressive organizations: MOPRC, which represents 47 local governments; the City of Columbus, which has extensive experience with economic development and sustainability; the American Electric Power, which supplies power to over 900 Ohio communities; TechSolve, which won the Emerald Sustainability Award in 2010; and the USBCED, a partner of the World Business Council for Sustainable Development, a global network of 200 international companies.

Participants not only leverage the networking, expertise and resources of these well-respected organizations, but they also receive a clean, green and lean technical assessment, as well as membership to the Ohio By-Product Synergy Network. Approximately 200 companies have been targeted to join.

Nationally, by-product reuse continues to grow. Michigan and Texas are strongly committed and there is renewed interest in reinvigorating Chicago's Waste to Profit Network.

By-product reuse networks provide many benefits to businesses and communities:

Extending the life of materials is economically, environmentally and socially important. By-product reuse is a powerful tool for moving communities along the path of sustainability. The pollution prevention network, through its technical assistance providers, regions, states, local governments, businesses and academia, is capable of taking by product synergy to the next level.